MINOR WEIR AND WILLIS LTD.

Successful Implementation of net zero Carbon Strategy and Sustainable Solution Projects

Client Summary

Minor Weir and Willis Ltd (MWW) is a long-established, family owned fresh produce business. The company operate throughout the fresh produce supply chain: as growers, packers and importers through some very long established partnerships and joint ventures. The business is a supplier to major retailers, the food service sector and the food manufacturing sector throughout Europe. The group has operated for more than 20 years in Spain, Holland and Germany, with newer operations in developing countries established in the last 5 years.

Sourcing over one hundred products from more than 40 countries and working closely with British growers to offer local produce when in season. The MWW group incorporates associate produce companies in the UK, Spain, Holland and Germany. These include growers, wholesale and catering suppliers and marketing companies, through which they can supply produce across Europe.

The company handle everything from exotic mangoes, pineapples and passion fruit to British-grown apples and pears. A lot of what is sourced is grown in tropical and sub-tropical countries in South America, Africa and Asia. There is a dedicated ripening team, who look after the produce throughout the ripening process, from field to shelf. Mango, avocado, papaya, kiwifruit – in fact, anything that needs that extra little bit of attention to ensure it gets to the supermarket shelf in perfect condition for the consumer.

The large salad range includes tomatoes, peppers and cucumbers supplied from growers in the UK and imported from countries including as Spain, Holland and Israel. Exotic vegetables are sourced from Africa, Asia, South America and Europe. Imported products include mange tout, baby corn, sweet potato, chilies and ginger. The facilities are backed by a dedicated distribution fleet wholly owned by the group.

The Old System

In 2014, MWW relocated the Perry Barr, Birmingham operation to the new Altitude site. This site incorporated the best available techniques and best practice on Low Carbon technologies to reduce energy consumption and carbon emissions at the new Head Quarter offices and packing facility.

|

Site |

Year |

Quantity |

Carbon tonnes (CO2e) |

|||||

|

Electric kWh |

Gas kWh |

Water m3 |

Electricity |

Gas |

Water |

Total |

||

|

Perry Barr |

2014 |

6,817,125 |

273,213 |

9,518 |

3,369.43 |

50.54 |

3.27 |

3,423.24 |

|

Altitude |

2019 |

3,181,112 |

133,880 |

3,179 |

813.09 |

24.61 |

1.09 |

838.80 |

|

2020 |

2,440,506 |

85,926 |

11,701 |

568.98 |

15.80 |

4.03 |

588.80 |

|

New System and Rationale

By 2020 carbon emissions from electricity, gas and water had reduced by 83% (equivalent to 2,800 tonnes of CO2e on 2014 levels. 2020 has been taken as the base year for setting future targets.

Delivering Net Zero Renewable Energy Projects - Solar Energy

Installing solar panels was seen as an excellent way to lower the business’ carbon footprint. It is a natural, renewable source which produces little or no emissions when it is converted to electricity.

685 kWp of solar panels were installed at the UK head office in 2019 which generated savings in grid usage and carbon emissions. Installing a further 500 kWp array at the head office/main pack house in 2023, took the sites investment in solar generation to over a £1,000,000.

Project Cost and Savings

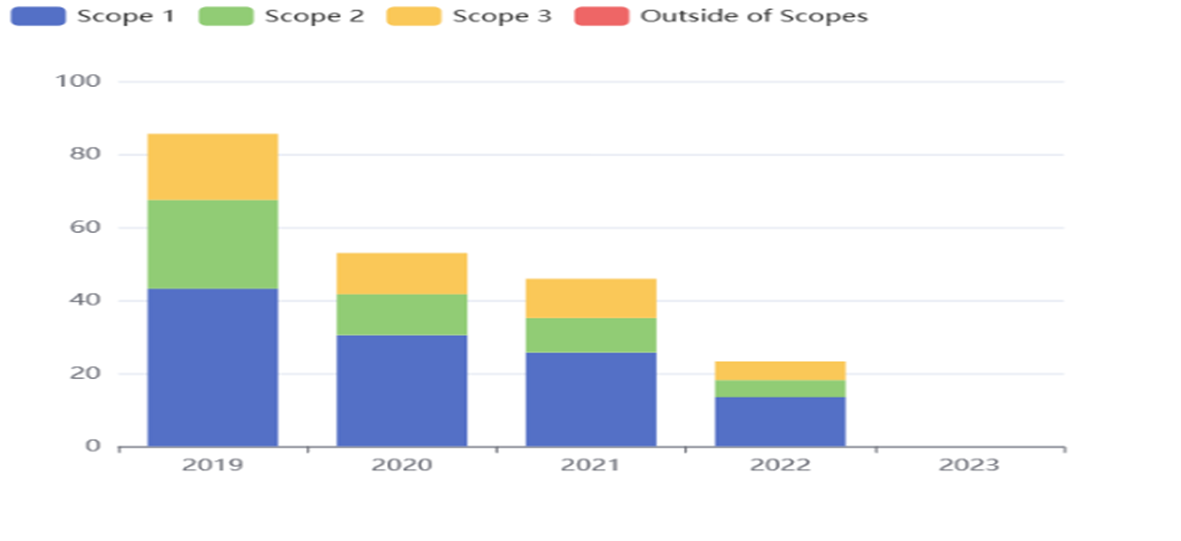

As a result of the significant investment in process optimisation and installation of renewable technologies, the company have made a significant reduction in CO2e emissions per unit of production when compared to 2019.

CO2e nemission per unit of production at Scopes 1, 2 and partial Scope 3

In recent years the business has also become a ‘zero-waste-to-landfill’ site; believing that great food should not end up in the waste bin, the company introduced a number of initiatives designed to specifically repurpose surplus food. For example, partnering with FareShare to send surplus fresh produce to local community groups and charities. In the last year, the company have redistributed more than 376 tonnes of surplus produce, which is equivalent to almost 900,000 meals for the people who need it most.

Utilising this surplus also has a benefit for the environment, with FareShare calculating that by redistributing this surplus MWW have saved 602 tonnes of CO2e and 564 million litres of water from going to waste. Any surplus produce which cannot be used in this way provides fuel of a different kind as it is sent to an Anaerobic Digestion (AD) plant where it is converted into biogas – a clean, net zero carbon source of energy.

Client Details

Contact Name: Parveen Mehta

Position: Operations Director

Email: Parveen.Mehta@mww.co.uk

Telephone: +441212894000

Address: Minor, Weir and Willis Ltd

Altitude, 206 Deykin Avenue

Witton,

Birmingham

B6 7BH

Pro Enviro Ltd.

For further details of MWW’s net-zero carbon strategy and decarbonisation of their operation, please contact:

Contact Name: Nersi Salehi

Position: Managing Director

Email: Nersi.salehi@proenviro.co.uk

Telephone: +44 1788 538150

Address: Pro Enviro Ltd.

8 Davy Court

Central Park

Rugby

CV23 0UZ